Conventional Cement Plug

Conventional Cement PlugApplication and Usage Method The plugs maintain separation of cementing fluids, wipe casing walls clean, and prevent cement contamination. When bumped against a float collar,

TIANJIN JINGGONG METAL PRODUCTS

TIANJIN JINGGONG METAL PRODUCTS

+86-13642008080

+86-13642008080

kylincoupling@sdccsy.com

kylincoupling@sdccsy.com

kylinpipe

kylinpipe

kylinpipe

kylinpipe

Conventional Cement PlugApplication and Usage Method The plugs maintain separation of cementing fluids, wipe casing walls clean, and prevent cement contamination. When bumped against a float collar,

Conventional Cement Plug

Application and Usage Method

The plugs maintain separation of cementing fluids, wipe casing walls clean, and prevent cement contamination. When bumped against a float collar, they provide positive indication of displacement and casing sealability.

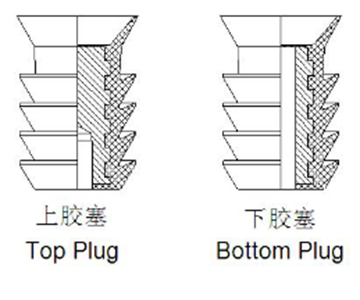

SS top cement plug & DS bottom plug are always used together. Top plug is used to isolate superior cement slurry and mud, prevent pollution, replace cement slurry to annular clearance.

Place bottom plug before injecting cement, pump the scrape to clean the well-wall, isolate lower cement slurry and mud, prevent pollution. Bottom plug is hollow struture. After all is setting, building the pressure 2-4Mpa till the rubber diaphragm is broke, and circulation is set. Then inject cement, place top plug, pump, pressure setting, well cementation finished.

Structure Features

1) . SS top cement plug, DS bottom cement plugs are designed and manufactured according to the demands of SY5394-91. The material of core is aluminium alloy or high polymer material with the good drillable capability. The plug is made by imported nitride butadiene rubber and having the good performance of anti-oil & anti acid-base. It has better features of scrape and replacement, because of the good structure of 5W.

2). The cementing plug contains Standard Cement Plug and Non-Rotating Cement Plug. Top and bottom plugs are used for double plug cementing. Top, middle and bottom plugs are used for two-stage cementing.

3). Standard plugs are designed for compatibility with all types of float equipment; Non-Rotating plugs are for non-rotating float equipment.

4). Secondary sealing and wiping fin on top and bottom plugs. Polyurethane fins for superior casing wiping and abrasion resistance.

5). Special anti-rotation mechanism is good for faster drilling-out.

6). Either PDC bit or roller bit drillable.

Model

Conventional (standard), Anti-rotation (non-rotating, anti rotary)

Specification

20”, 18-5/8”, 13-3/8”, 10-3/4”, 9-5/8”, 8-5/8”, 7-5/8”, 7”, 6-5/8”, 5-1/2”, 5”, 4-1/2”, 3-1/2”, 2-7/8”

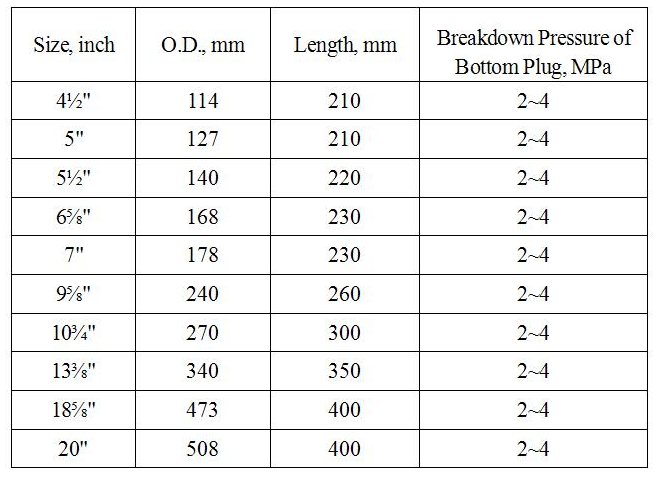

Technical Parameters